Jump to Sections:

- Improve ROI and Extend Equipment Life with Ongoing Maintenance Processes

- 8 Simple Steps to Maximize Heavy Equipment Machine Life

- Establish a Heavy Equipment Maintenance Checklist

- How MacAllister Helps You Get There

Improve ROI and Extend Equipment Life with Ongoing Maintenance Processes

Heavy Machinery is the most expensive construction equipment you own. It’s also the costliest to repair or replace. This guide will show you how to save money and extend the life cycle of your equipment with regular maintenance best practices.

We’ll identify commonly overlooked areas of maintenance, and identify simple things you can do to greatly impact the long-term value of your most vital equipment. Even the most powerful and dependable Cat® machinery requires basic attention to ensure it provides the exceptionally long service life and unmatched productivity of Cat construction vehicles.

Why You Need to be Proactive About Machine Maintenance

Being proactive in your heavy equipment maintenance schedule helps prevent expensive downtime. Regular maintenance helps predict when failure is likely to occur, allowing you to find a solution to problems before they happen.

Let’s look at this in terms of real dollars. Preventive maintenance can reduce machinery repair bills by 25 percent.

An example is an $80,000 machine that requires approximately $24,000 in maintenance and repair costs during 5,000 operating hours. By implementing sound preventive maintenance tips, this maintenance cost drops by 25 percent to $18,000.

8 Simple Steps to Maximize Heavy Equipment Machine Life

Here are 8 Simple Steps you can begin today to improve the ROI and extend the service life of your construction equipment.

#1 — Commit to a Preventive Maintenance Program

Preventive Maintenance (PM) helps anticipate change, and wear and tear. Corrective actions are taken continuously to ensure reliability and performance. PM involves regular systematic inspections, modification and replacement of components as well as performance testing and analysis.

Preventive Maintenance (PM) helps anticipate change, and wear and tear. Corrective actions are taken continuously to ensure reliability and performance. PM involves regular systematic inspections, modification and replacement of components as well as performance testing and analysis.

A successful preventive maintenance program extends construction equipment life and minimizes unscheduled downtime caused by equipment breakdown. Benefits from a proper PM program include:

- Improved equipment and system reliability

- Reduction of unexpected breakdown

- Decrease in expensive parts replacement

- Extended equipment life

- Improved resale value

- Better parts inventory management

Preventive maintenance is more than regular maintenance like lubricating and changing and filters. A proper preventive maintenance (PM) program is all-inclusive. It’s an intentional approach to equipment management from the time equipment is purchased until the end of its useful life.

Your Preventive Maintenance program can include any or all of these customer value agreements:

- Total Maintenance and Repair Agreements

- Machinery Inspection Programs

- Site Inspections

- Field Service

- In-Shop Service

- Diagnostic Technology

- S-O-S Fluid Analysis including Fuel, Oil and Coolants

- Failure Analysis

- Product Link On-Board Analysis

- Condition Monitoring

- Electronic Information Collection

- Machine Inspection Data

- Historical Repair Data

- Component Rebuilds

- Component Tracking

- Specialized Repair Tooling & Equipment

- Equipment Management Software

- Customer Training Seminars

- Training and Safety Videos

#2 — Identify Major Causes of Machinery Breakdown

Part of an effective PM program is identifying potential causes of machinery breakdown. By identifying potential causes of failure before they occur, you can save hundreds or thousands of dollars and maintain consistent work flows.

There are three types of machinery failure. Their causes and solutions are listed below.

- Sudden failure is when machinery breaks without warning. Usually, the reason is obvious. The part is then fixed or replaced, and the equipment is returned to service.

- Intermittent failure happens sporadically. This stoppage happens randomly, and it can be difficult to identify the cause. Intermittent failure is frustrating, costly in downtime and usually can be prevented by anticipating the cause and addressing it during maintenance.

- Gradual failure is entirely preventable by doing routine maintenance and inspections. Wearing parts and components are noted to be near the end of their lifespan and are replaced before failure occurs.

These three types of machinery failure are almost always due to one of three main causes:

- Thermally induced failure is where extremes in temperature cause break-downs in the equipment. This usually happens during large temperature fluctuations such as when a machine is being started in cold weather and is being warmed up. It also occurs when equipment is overheated. Extremely hot or cold periods can be prepared for during maintenance, and thermal failure can often be prevented.

- Mechanically induced failure is easy to recognize. It’s also easy to prevent by making sure machinery components are maintained by replacing parts when needed, lubricating as required and tightening fasteners, as well as ensuring moving parts are properly aligned. Mechanical failure often happens due to overexertion, vibration, shock, collision and operator abuse.

- Erratic failure is the most difficult to predict and detect. This occurs at random times and under varying conditions. Most erratic machinery failures are the result of sudden overloads on hydraulic or electrical systems. With electronic components, many erratic failures come from software or hardware malfunctions that are preventable by using diagnostic equipment during regular machinery maintenance.

Anticipating failure is at the heart of all preventive maintenance programs. Thorough knowledge of your machinery’s systems is the key to anticipating what’s likely to fail if proper maintenance is ignored. Cat Preventive Maintenance Agreements from MacAllister Machinery help you anticipate and predict problems before they leave your equipment inoperable.

#3 — Get to Know Your Machines Inside and Out

Thorough product knowledge is invaluable when it comes to implementing an effective preventive maintenance program. Often, gaining this vital information is as simple as finding it in the machine’s equipment manual that has been researched and documented to isolate issues and prescribe the proper preventive maintenance.

Taking the time to read and understand the equipment manual should be a core principle in a PM plan. Manuals will prescribe the recommended service intervals for each component in the machine, what servicing products to use and what the acceptable operating conditions are for the equipment.

Owner’s manuals are also a great source of troubleshooting information. Not only do manuals prescribe maintenance steps and techniques, but they often have bullet-point itemization or flow charts of what to do during malfunctions.

Listen to Your Operators

Another valuable resource for getting to know your machines inside out is to involve the machine operators. Unless you’re on the controls on a daily basis, you’re not likely to have the intimate knowledge of each machine’s idiosyncrasies and quirks. Daily operators get a “feel” for the machine. Operators sense when something’s amiss, and they’ll tell you. Listening to them and appreciating their input is a wise preventive maintenance strategy.

Stop Operations When You Suspect a Problem

Stopping operation and dealing with a suspected problem between scheduled maintenance periods can be an enormous savings in failure costs and subsequent losses.

Don’t restrict maintenance to rigid schedules. Instead, allow the flexibility to respond with proactive intervention.

#4 — Train Your Employees in Effective Machinery Operation

Knowledgeable machinery operators are more productive and cause less wear on machinery than untrained workers. Knowledgeable operators are also going to be safer to themselves and others working nearby. Properly trained operators will be more respectful of their equipment and more likely to look after it before, during and after construction duties. That’s going to save you money in repairs and replacement.

Operator training should be built into your preventive maintenance program. Operators have to know more than just how to start and run their machinery. They need to be aware of what routine, day-to-day maintenance tasks are required and how to perform them without fail.

Operator training can include a review of the operator’s manual, demonstration of the systems and all controls. Testing can be a part of training as well to ensure operators have acquired the right skills including pre and post operation maintenance tasks.

Additionally, checklists for operators are valuable tools, so minor but important maintenance steps are done and not forgotten.

The training process doesn’t have to be complicated or lengthy. Clear communication about a machine’s limitations as well as instruction on the controls and monitoring systems will help increase the life of your vital machines.

Trained operators are frontline reporters of any damage or early warning signs that a machine is heading toward failure. Operators trained to recognize failure indicators and to bring them to your attention are exceptional insurance that minor, inexpensive issues don’t become big and costly problems.

At MacAllister Machinery, we make training one of our highest priorities. Our technicians and service representatives can assist you in developing operator training by including it in a Customer Value Agreement.

#5 — Adhere to Factory-Recommended Maintenance Intervals

All Cat equipment we handle at MacAllister Machinery is supplied with detailed manuals from the factory that include a heavy equipment maintenance schedule. This extremely valuable resource has been painstakingly assembled through the knowledge, talent and experience of Cat designers and engineers. No one knows more about the right maintenance intervals for their machinery than Cat.

Factory-recommended maintenance intervals are a minimal standard and are based on normal operating conditions. This may vary depending on local climate and specific site environmental concerns like dust, mud, humidity, ice, snow, rain and excessive temperature fluctuations. It can also vary according to the operator load that’s put on the machine.

Following factory-recommended maintenance intervals and keeping precise records is important not just for economical operation of your machinery, but also to protect your warranty.

Failing to maintain your machinery according to factory specifications and suggestions may void the warranty. A warranty from Cat is comprehensive and covers all equipment components. However, this warranty is valid as long as the machinery has been operated as designed for its purpose as well as maintained at the recommended intervals.

#6 — Document Your Machine’s Service History

Keeping detailed service records is an important component in your preventive maintenance plan. It’s impossible to mentally keep track of what type of servicing has been done on your machinery, and that includes when maintenance was done and when it needs to be done again.

Documented service records let you keep an accurate picture of a particular machine’s history. Routine and regular interval servicing should be written in a booklet kept in your maintenance facility or even in the machine itself. This should include the date, what type of servicing was performed, what parts were replaced, when the next regular servicing is required and notations as to any peculiarities or irregularities that were observed.

Service records don’t just provide a chronological record of the maintenance of machines. Detailed maintenance records give you documented proof that your machinery has been maintained according to the manufacturer’s recommendations. This is important for daily operations, but it also strongly supports any warranty claim where there may be a dispute that mechanical failure was caused by neglect to perform the required maintenance.

Documenting your service tasks can be done by using a pen on paper ledger. It can be on a computer file using a spreadsheet or stored in a manual file kept in your office drawer along with other paperwork associated with the machine. Small booklets placed on the machine are common. Whiteboards on office walls are another simple and proven technique for seeing heavy equipment maintenance schedules at a glance.

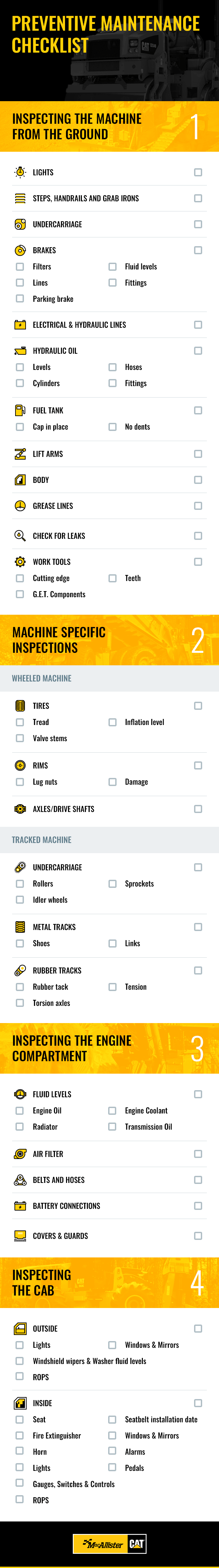

Establish a Heavy Equipment Maintenance Checklist

A heavy equipment maintenance checklist is highly recommended to aid in remembering tasks and ticking them off as servicing is complete. Organize check-sheets with each itemized task associated with certain intervals. That might be daily, monthly or seasonally. It also may be according to machine time where certain hourly milestones need specific attention.

Documenting your machinery servicing lets you plan for future tasks. This includes being reminded to order replacement parts, fluids and filters, as well as scheduling maintenance that needs outsourcing to a dealer where shop-time is required or a dealer site visit is requested.

Use our handy equipment maintenance checklist below or download as a printable PDF.

This work is licensed under a Creative Commons Attribution-NoDerivs 3.0 United States License.

Start Your Inspection From the Ground

The first part of any preventive maintenance checklist should be done from outside the vehicle.

- Lights: If your vehicle has any lights — headlights, brake lights, warning lights, etc. — they should be inspected to ensure they are working properly. Any burned-out bulbs should be replaced.

- Steps, handrails, and grab irons: Ensure all these grab points are secure and that they aren’t rusty or damaged, which could make them dangerous.

- Undercarriage: This is especially important if you work in areas where it snows or your equipment is exposed to salt or road de-icing chemicals. Inspect the undercarriage for signs of rust or damage.

- Brakes: This step has a variety of things you will need to inspect, including the filters, fluid levels, lines and fittings, and the parking brake. If any of these things look like they’re getting ready to fail, it is a good idea to take the equipment off the floor until it can be repaired.

- Electrical lines: Inspect any exposed wires to ensure their insulation is intact.

- Hydraulic lines: Inspect these lines for any signs of leaks that could cause equipment failure.

- Hydraulic oil: The oil that is carried through the hydraulic lines needs to be inspected, too. Look at the oil levels, and check the hoses, cylinders and fittings for any leaks.

- Fuel tank: The cap should be in place on a fuel tank, and the tank itself should be inspected to ensure there are no dents in the metal that could weaken the tank and lead to leaks.

- Lift arms: If the equipment has any lift arms, they should be inspected and checked for rust, leaky hydraulics and other weak points.

- Body: Inspect the body of the equipment for rust, damage or other potential problem points.

- Grease lines: If your equipment has grease lines, check them for leaks.

- Check for leaks: Other places that leaks could occur might be in coolant lines, fuel lines or tires.

- Work tools: For any smaller work tools, make sure to inspect their cutting edge or teeth to see if they need sharpening.

Machine-Specific Inspections

The inspections you do will vary depending on the exact specifications of the machine.

- Wheeled machines: On machines with wheels, you will need to check the tires and make sure the valve stems and the tire tread are in good repair. Make sure the tires are also inflated properly. Rims should be inspected for damage, and lug nuts should all be in place and tight. Axles and drive shafts should also be inspected for damage or rust.

- Tracked machine: For machines with tracks instead of wheels, you will need to inspect the rollers and sprockets in the undercarriage for signs of rust or wear. Idler wheels should also be inspected to ensure they aren’t damaged and that they spin freely. Metal track shoes and links should be inspected for damage. Rubber tracks should be inspected for tension and the tack of the rubber. The torsion axles on these machines should be checked for rust or damage.

Inspecting the Engine Compartment

Once the exterior of the machine has been examined, the next step is to look under the hood.

- Fluid levels: Oil, engine coolant and transmission oil levels need to be checked. Any fluids that are lower than their optimum level should be refilled, and the equipment should be checked for obvious leaks.

- Air filter: Check the oil filter to see if it is dirty and needs to be replaced. These filters should be replaced regularly anyway, but a dirty filter can make your engine run poorly.

- Belts and hoses: Belts should be inspected for signs of undue wear. They should be tight on the pulleys, but should not be pulling so hard that the pulleys themselves are damaged. Hoses should be inspected for leaks, and for signs of wear or dry rot.

- Battery connections; Battery terminals should be inspected for signs of corrosion and replaced if they are damaged.

- Covers and guard: Any existing safety covers or finger guards should be inspected to ensure they are in good shape. Any damaged covers should be removed and replaced.

Inspecting the Cab

Finally, you will want to inspect the cab of the equipment.

- Outside the cab: Again, inspect any lights in the cab to ensure they’re working. Windows and mirrors should be inspected for clarity and any chips or cracks. Washer fluid levels should be checked, and any windshield wipers should be inspected for wear. Finally, ROPS should be inspected for any undue wear and tear.

- Inside the cab: First, inspect the seat to ensure it is in good working order. Seatbelt installation dates should be checked. Recheck the mirrors and windows from the inside of the cab for any chips or cracks that aren’t visible from the outside. Make sure the pedals move easily and that all lights that are controlled from inside the cab turn on and off smoothly. If you keep a fire extinguisher in your cab, inspect it to ensure it is properly charged and has been inspected recently.

Preventive maintenance can help catch small problems before they become big ones that might completely sideline your equipment. It might take a few extra minutes every day, but it’s worth it in the long run.

MacAllister Machinery provides site inspections and in-shop service as part of our preventive maintenance programs included in a Customer Value Agreement. We also provide diagnostic technology with technical analysis to thoroughly inspect each major system of your machine. Including this extensive computer diagnostic lets you automatically record if you’ve completed maintenance tasks like scheduling fuel, oil, coolant and hydraulic fluid sampling.

#7 — Pay Close Attention to What Your Machinery’s Fluids Are Saying

Perhaps nothing is so important, and so often overlooked in machinery maintenance, as fluid levels. Analyzing engine oil, fuel, coolant and hydraulic fluid tell an internal tale describing the health of your machine. These analyses are also indicators of maintenance effectiveness and predictors of potential failures.

Here’s how fluid analysis benefits you:

- Detects problems early, so they can be repaired before they become major failures

- Helps you schedule downtime to fit your workload

- Helps you develop a complete service history for each machine

- Improves Resale or Trade-In Value

For maximum protection, you need oil sampling for all major oil lubricated systems (engine, transmission, hydraulic system and final drives) and coolant sampling for your cooling systems. By pinpointing fluid troubles early, you can avoid shutdowns for unplanned repairs and even catastrophic failures.

#8 — Monitor Your Machinery’s Overall Condition

Owning and operating heavy construction machinery is a large undertaking. Your investment is nothing to gamble with. This goes beyond regular fluid maintenance.

Owning and operating heavy construction machinery is a large undertaking. Your investment is nothing to gamble with. This goes beyond regular fluid maintenance.

Condition monitoring should be an overall part of your preventative maintenance plan to prevent breakdown and avoid unnecessary repair costs that rob you of efficiency and profit. Partnering with MacAllister Machinery delivers the support you need to complete projects on time and under budget. Cat Condition Monitoring is a proactive approach to collecting and analyzing data crucial to the health of your fleet.

MacAllister Machinery provides tools, techniques and expertise to empower you to better understand the condition of your equipment. We’ll make accurate recommendations and provide necessary support to help your operation reach its full potential.

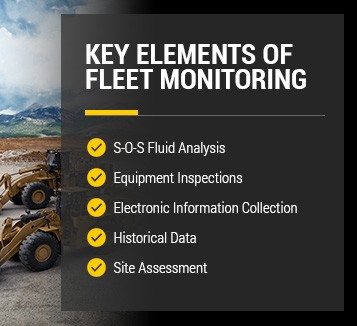

Condition monitoring by MacAllister Machinery is a comprehensive service designed to accurately assess the health and activity of your heavy equipment. The key elements involved in the process of monitoring your fleet are:

- S-O-S Fluid Analysis — Advanced fluid diagnostic capabilities allow you to better assess the condition of your equipment. We use the latest technology to analyze oil, coolant, component wear and other key contributing factors to determine overall machine health.

- Equipment Inspections — The most effective way to identify maintenance issues is through frequent inspections. We’ll not only assist in analyzing data collected, but we’ll also train your team to learn how to spot and correct maintenance issues before they contribute to costly breakdowns and repairs.

- Electronic Information Collection — Technology directly installed into your equipment transmits operating data wirelessly through the Product Link system. This provides a real-time picture into the health, activity and availability of your fleet. We install all components and provide the expertise to harness data necessary for making key adjustments that improve operational efficiency.

- Historical Data — Cat condition monitoring includes collecting, organizing and responding to equipment service reports and historical documentation. We analyze the data and make accurate recommendations for maintenance, inspections and repairs that reduce operating costs and increase lifecycle performance.

- Site Assessment — There are many internal and external factors that combine to impact your bottom line. Site condition assessment evaluates everything from long-term equipment performance and maintenance history to work environments and seasonal weather conditions for deeper insight into how to be more productive.

Get in touch with the experts at MacAllister Machinery for PM Agreement information and additional construction equipment maintenance tips.

Regular care and preventive maintenance of machines are priorities for heavy equipment. That includes routine machinery maintenance you do as the owner as well as outsourced maintenance with assistance by Cat equipment professionals like you’ll find at MacAllister Machinery.

How MacAllister Helps You Get There

MacAllister Machinery offers an all-in-one solution for managing your fleet of Cat equipment at a cost that makes sense for your budget. It’s called a Cat Preventive Maintenance (PM) Agreement, and it will keep your equipment operating at peak performance through comprehensive preventive maintenance

A PM Agreement puts the complex task of monitoring sophisticated machinery and analyzing performance data in the hands of experts. Over time, our PM Agreements lead to lower costs associated with owning and operating your fleet.

When you sign a PM Agreement with MacAllister Machinery, you benefit from:

- Convenient, timely service in our facilities or at your work site

- Professional support from factory-trained technicians

- Emergency response and after-hours service

- Complete documentation of equipment service history data

- Regular inspections and S-O-S fluid analysis for early detection

- Flexible scheduling

- Competitive, fixed pricing

As your authorized Cat dealer for Indiana and Michigan, we offer state-of-the-art capabilities in preventive maintenance. We’ll assist in analyzing your heavy equipment, applications and requirements to help build a customized plan to improve the efficiency of your fleet, save you money and improve your ROI. Fill out a MacAllister Machinery contact form today to request maintenance on your machinery.